HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin Asano Uses Geomagic 3D Scan Software to Drive In…

Asano Uses Geomagic 3D Scan Software to Drive In…

Rebuilding A Classic Car With 3D Scanning And Reverse Engineering from 3D Systems Geomagic

Brian Coombs Design uses a Solutionix structured light 3D scanner together with Geomagic reverse engineering software to solve a âvolume claimâ packaging problem in a project to rebuild a replica Ford GT40 classic sports car

by Neil Mcleod

Speed seems to be part of Brian Coombs’ life. As engineering lead for mechanical design at Bloodhound SSC, the UK’s project to retain the World Land Speed Record with a jet and rocket-powered 1000mph (1610km/h) car, he leads a team of engineers that is responsible for the design of the mechanical structure and suspension system for the car.

As if that weren’t enough of a challenge, though, in his spare time at his home in Ireland he is upgrading the engineering of and rebuilding a replica of the classic Ford GT40 sports car.

The GT40 packs quite a punch with its tuned, 5-liter V8 engine. Unfortunately, though, the engineering on the old replica GT40 that Coombs bought as a kit car some years ago can’t always handle it. In particular, he notes, the gearbox has a tendency to fail under the power it has to handle.

“A suitable replacement gearbox for this car is very expensive”, states Coombs. “So as part of the project to rebuild the car and at the same time upgrade some of the engineering aspects of it, so it is better able to handle the power, I decided to build my own gearbox using the internal parts that I had from of an old Reynard Indy racing car.”

With his background in design engineering in the motorsport industry – he has worked for the Red Bull Racing Formula 1 team amongst other motor racing teams over the years – he has the skills and know-how required to do this. He is also used to working with today’s CAD/CAM technologies. So rather than using only traditional manual methods to rebuild his car, Coombs has set up his own machine shop and has access to 3D CAD, in the form of Siemens NX software, to redesign certain parts of the car and to create a 3D digital CAD model of it, from which new parts could be manufactured.

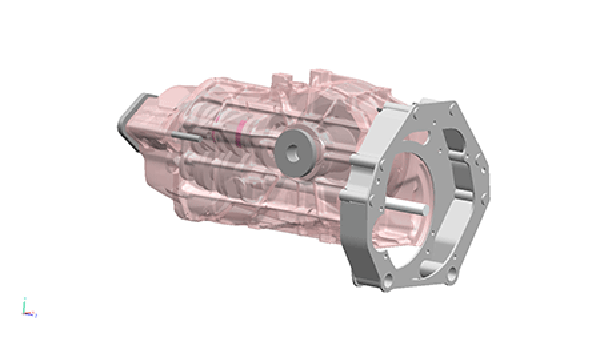

Image: The gearbox casing selected by Brian Coombs to house the new gearbox for his Ford GT40 replica.

All the same, the gearbox design presented something of a challenge. Bearing in mind that he was making the gearbox out of existing components, how was he going to ensure that, once complete within a suitable casing, it would fit into the available space in the car’s engine bay, that it didn’t foul other parts of the car and that it would align correctly with other components? He could build a physical mock-up, maneuver this into place manually and take the measurements he needed. But this would be very time-consuming – and time is something of which Coombs doesn’t have much to spare.

The answer came from the UK office of 3D scanner manufacturer, Solutionix. Using one of their Rexcan scanners, they could scan the gearbox casing and then use Geomagic reverse engineering software to create an accurate 3D digital model of it from the scan data. This model could then be used for ‘volume claim’ packaging purposes in Coombs’ CAD system.

3D Scanning

The 3D scanning process is where speed comes into Brian Coombs’ life yet again. A Rexcan 420 from the Solutionix range of Rexcan structured-light 3D scanners was used to capture the shape of the gearbox casing. Having twin CCD cameras with resolutions up to 8 megapixels and using phase-shifting optical triangulation technology, the Rexcan 4 is capable of capturing millions of 3D coordinate points per second to an accuracy of +/- 20 microns.

The scanner was used in conjunction with a Solutionix automatic turntable that can handle items weighing up to 70kg. With the gearbox casing mounted on the turntable, the scanner was set up to look down on it at 45 degrees. With Solutionix ezScan software controlling and coordinating the turntable’s motion and the scanner’s data capture processes, scans of the upper half of the casing were taken automatically at increments of 10 degrees as the turntable rotated through 360 degrees. The casing was then turned over and the process was repeated in order to capture the lower half.

In all, 72 individual scans were taken in a session lasting about an hour. Using the Solutionix ezScan software, these individual scans were registered with each other automatically as the scanning was proceeding to create a single 3D point cloud model of the gearbox casing which was then converted by the scanning software into a single, merged polygon model.

Although comprising only about a fifth of the total number of polygons contained in all the individual scans, the merged scan data model still comprised some 10 million polygons. So to speed up subsequent processing of the data, the model was sampled, reducing the polygon count in flat areas while retaining it in high curvature areas. This reduced the polygon count to around 1 million without affecting the model’s accuracy.

Image: The final Geomagic surface model of the gearbox casing generated from the Solutionix Rexscan 4 scanner data

3D Surface Model

The next step was to convert the polygon model into an accurate 3D digital surface model suitable for use in the CAD system. For this, it was exported from the Solutionix scanning system into Geomagic. This is used around the world to convert the data captured in 3D scans of physical objects into ‘watertight’ 3D digital models for use downstream in a wide variety of applications, from CAD, engineering analysis, recording archaeological finds and works of art, to custom product design and rapid manufacturing.

The first step was to repair the polygon model where required, using Geomagic’s standard tools to fill holes in the model where the scanning process had not succeeded in fully capturing certain parts of the casing. This process, which took no more than 10 minutes, resulted in a single, fully closed – or ‘water-tight’ - 3D polygonal model.

Next, the software’s ‘Create Features’ function was used to select and identify simple geometric features, such as cylinders, holes, and planes on the model that would be used to provide a geometric reference within the CAD system.

The final step was to use the software’s AutoSurface command to convert the polygon model, incorporating the geometric features, into an NURBS (non-uniform rational b-spline) surface model. This was a simple, 2-clicks automatic process that took around two minutes to calculate. A straightforward ‘3D Compare’ between the polygon model and the surface model was then used to confirm the geometric integrity of the final surface model.

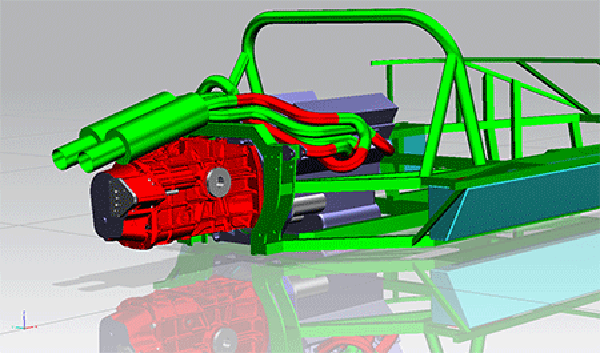

Image: An assembly model of the gearbox casing and bell housing.

With that done, the final model was ready to be exported to Coombs’ NX CAD system as a STEP (.stp) file where it could be used as a volume claim model within the 3D CAD model of the car’s chassis, sub-frame and suspension system. This would ensure that, when it came to physically installing the new gearbox, it would fit into its space and align correctly with other parts.

Image: The Geomagic gearbox model (in red) positioned within the NX CAD model of the GT40’s structure.

Need for Speed

The whole process of scanning the gearbox casing and creating an accurate 3D digital surface model of it took about two hours from start to finish.

As Coombs explains, “I don’t have a lot of spare time to spend on my GT40 rebuild project. So the near-automatic scanning process using the Solutionix scanner and turntable, along with the automatic processing of the scan data provided by the Solutionix ezScan and Geomagic, most of which is accomplished with just one or two mouse clicks, saved a lot of time.”

But the need for speed didn’t mean compromising on quality.

“Although it took only two hours to produce a 3D digital model of the gearbox casing, which was impressive enough, I was impressed with the resolution and accuracy of the original scan data. I was also impressed with the quality of the final 3D digital surface model and the way this could easily be incorporated into the CAD model,” says Coombs. “This meant I could be confident that what I was doing in the virtual world would work in the real world on the car.”

And when the work is complete, speed will feature once again in Coombs’ life. He plans to enter his reengineered and rebuilt Ford GT40 replica in the occasional race.