HOT

Xsens’ new MTi 600-series wins AUVSI XCELLENCE …

Xsens’ new MTi 600-series wins AUVSI XCELLENCE … The Future Group, Xsens and IKINEMA partner up

The Future Group, Xsens and IKINEMA partner up Live data analysis of the long jump at the FBK G…

Live data analysis of the long jump at the FBK G… Xsens and Ergoneers join forces to launch ergono…

Xsens and Ergoneers join forces to launch ergono… New MTi 600-series industrial-grade inertial sen…

New MTi 600-series industrial-grade inertial sen… Xsens North America Celebrates New Office Grand …

Xsens North America Celebrates New Office Grand … Xsens’ latest update takes outdoor motion captu…

Xsens’ latest update takes outdoor motion captu…

5 Reasons to Modernize Your Product Development Processes NOW!

It’s exciting to read about the latest advances in product design and manufacturing technology. From generative design offering automated lightweighting possibilities, to 3D printing creating previously impossible shapes, and the Internet of Things (IoT) connecting millions of devices across the globe. At the same time, the idea of implementing new technology and processes into your existing workflow might feel like you are trying to jump onto a treadmill that’s already going at full speed.

How do I integrate new tools without disrupting my current production schedules? How do I train my teams to use these tools effectively? And how can I justify the software and implementation costs this might require? Do we have the right expertise to develop a connected product? Luckily, it’s never been easier or a better time to modernize your company and start realizing the many benefits of simulation-driven product development!

1. Concept Design Software Is More Intuitive Than Ever

In traditional product development processes, designers have limited access to information about design feasibility, durability, manufacturability, and expected performance. They have to rely on engineering teams to discover where modifications are needed to meet production criteria, resulting in costly and time-consuming redesign iterations that sometimes mute or eliminate the creative and bold design decisions that would have made the product stand out. But what if designers were empowered to ask and answer these questions at the concept stage?

Now, intuitive, designer-focused software can give design teams engineering knowledge without the need for extensive training. Altair SimSolidTM can deliver structural simulation results directly from native CAD models in seconds eliminating the need for meshing. The Altair InspireTM Platform gives designers the ability to model and morph with powerful polynurbs capabilities, run topology optimization for material and weight reduction, and even set up loads and dynamic motion paths to understand how parts and assemblies will behave under real-world conditions. Coupled with photorealistic rendering features, a designer has everything they need to create an optimized product prior to engineering analysis validation, thus streamlining the entire process.

2. Reap Immediate Cost Benefits by Taking Physical Testing Virtual

It’s a huge effort to get to the physical testing phase of a project, so when a critical issue is discovered, it’s often “back to the drawing board”. You redesign, you re-analyze, and cross your fingers that the next physical test gives you the results you’re looking for. The time and cost associated with multiple redesigns put extreme pressure on the entire organization, so finding a “first-time-right” approach is absolutely critical.

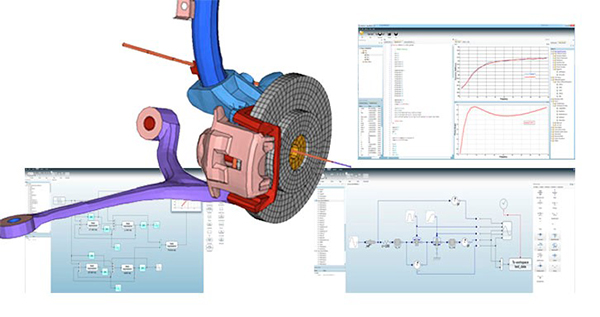

With a simulation-driven product design approach, you can consider hundreds or even thousands of design iterations, optimized based on customizable criteria like cost, weight, materials, strength, durability, and more. Multiphysics simulation even enables you to do multidisciplinary studies like structural, thermal, and fluid dynamics analysis to find the perfect harmony of performance in your design.

3. Dump the Trial and Error with Simulated Manufacturing Feasibility

You’ve found the right materials, you’ve optimized to save mass and material costs, and your simulations say that the design will hold up to the structural requirements, but every product designer knows that the job isn’t done until it’s actually manufactured. Machine tolerances, inconsistent cooling temperatures, environmental factors, and a myriad of other influences can cause the part to fail when it goes into production. Additive manufacturing and other advanced manufacturing processes add even more complexity into the process. So how do you anticipate and mitigate these risks and ensure the part you see on screen and in prototype tests performs to the same standards in the hands of the customer?

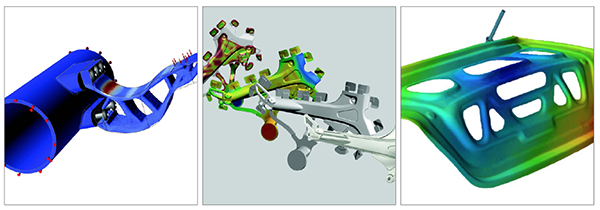

As with virtual prototyping, manufacturing process simulation can take the guesswork out of the production process. Control overhang shape and find the ideal print orientation for additive manufacturing. Simulate forming, casting, injection molding, or extrusion for metals or polymers, all with the benefits of optimizing material utilization, productivity, and cost.

4. Get on the Ground Floor of the Cloud Based 4. Digital Transformation

One of the biggest historical hurdles for small and medium business interested in simulation has been the lack of availability and budget for compute resources. But now, with cloud simulation, virtual on-demand high-performance computing (HPC) resources, and workload management and administration tools, we’re seeing a democratization of resources and a leveling of the playing field. New delivery models allow companies of all sizes to tap into the resources they need, when they need them.

The products of tomorrow are also getting smarter, and companies that embrace the trends of IoT, digital twin, and Industry 4.0 are already seeing the benefits. Advanced analytics, artificial intelligence, and machine learning are enabling new levels of insight and innovation, while IoT platform services drive the digital transformation and open the possibility for active device management and in-service monitoring.

However, The decision to connect your devices and modernize your computing processes is not simply a choice of software. Altair is an industry leader in both software development and deployment partnership, providing the expertise needed to help you customize these services to your exact specifications.

5. Everything You Need to Get Started – Software Discounts, Expert Consulting, and Training

Cutting edge simulation processes, computing resources, and data intelligence will be one of the deciding factors elevating the innovators of tomorrow, and Altair has the software and expertise to guide your company to reach its highest potential.

Altair Elevate is a limited-time new customer incentive that offers up to 50% off your first software purchase. Many customers also qualify for 16 hours of free expert consulting services to help get your teams up and running. Altair also offers online training resources and 24-hour support to ensure you’re empowered from concept to reality.