HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin Asano Uses Geomagic 3D Scan Software to Drive In…

Asano Uses Geomagic 3D Scan Software to Drive In…

Prosthodontist Achieves Same-Day Dentures with NextDent 5100

Dr. Michael Scherer is a prosthodontist in Sonora, California, located ten miles from the heart of the Stanislaus National Forest and 100 miles southeast of Sacramento, the nearest city. A long-time advocate of technologies that help him enhance patient care, Dr. Scherer transitioned to intraoral 3D scanning several years ago to spare his patients the uncomfortable and messy experience of taking composite impressions. Eager to extend the value of these digital scans, he began experimenting with 3D printing. He ordered two 3D Systems’ NextDent™ 5100 3D printers for his office shortly after its launch and says they provide him with an all-in-one solution for producing actual 3D printed dental restorations at an efficient time point.

The speed of the NextDent 5100 enables same-day dentures to enhance patient care.

Due to Dr. Scherer’s rural location, his patients typically travel anywhere from 30 minutes to several hours to get to his office. For dentures, implants and bridgework, multiple visits are common practice to address various stages of traditional fitting and delivery. The need for multiple appointments to achieve a conventional restoration can make seeking treatment time consuming and challenging for the patient; a burden Dr. Scherer hoped to alleviate through in-house 3D printing. Dr. Scherer reports that the addition of the NextDent 5100 printers to his office has accelerated his workflow and changed his patients’ experience, and says he can no longer imagine his practice without them.

Fast print speeds enable same-day dentures

The new capabilities in dental care enabled by the speed, accuracy and esthetics of the NextDent 5100 3D printer have helped Dr. Scherer deliver a superior patient experience. In particular, the ability to cut total denture delivery time from five or six appointments to a process that can be completed in the same day. For elderly patients who rely on others for transportation to and from appointments, Dr. Scherer says this new capability makes treatment possible by removing logistical barriers: “The NextDent 5100 enables me to do things in my office – like expedited dentures – that I couldn’t do before, and it’s having a real impact on my patients’ lives.”

By running two NextDent 5100 printers simultaneously, Dr. Scherer can have a denture ready in 20 minutes.

3D Systems’ NextDent materials are biocompatible and CE-certified, and are available in a wide selection to answer a broad range of clinical needs. This allows Dr. Scherer to use the NextDent 5100 not only for same-day, long-term dentures, but for expedited implants, crowns, bridges, bite guards and more. “Combining intraoral scanning technology with fast, accurate and esthetic 3D printed teeth is the great, bring-it-all-together moment we’ve been waiting for in dentistry for years,” Dr. Scherer says.

To illustrate his case, Dr. Scherer cited an anonymous example of a patient who was moved to tears after receiving their denture in a same-day appointment. “I got the NextDent 5100 printers for patients like that, who need an option for treatment that makes it feasible,” Dr. Scherer says. Due to the loss of a loved one, the patient told Dr. Scherer they could no longer make multiple long drives for sequenced appointments. Understanding that, Dr. Scherer assured them the denture could be done in a single visit using innovative methods.

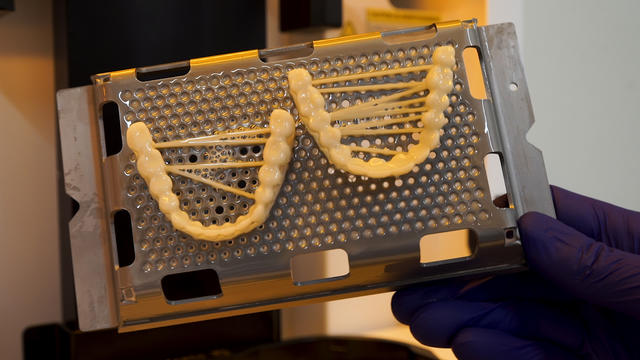

Eager for treatment, the patient made an appointment and came in in the morning for an intraoral scan. Dr. Scherer used the digital model to plan the denture, and his assistant ran the 3D printers, producing the denture teeth in the first and the denture base in the second for delivery by early afternoon of the same day. When the new denture was delivered, the patient saw their new smile and started crying, saying they never imagined how beautiful 3D printed teeth could be. “With the two NextDent 5100 printers I can have the denture teeth printing in one printer and the denture base printing in another printer, and have a denture ready in 20 minutes,” Dr. Scherer says.

The NextDent 5100 printers have reduced wait times considerably for other restorations as well. Depending on the model to be printed, Dr. Scherer is experiencing print times of ten to forty minutes with the NextDent 5100 compared to two- to four-hour print times for comparable models on other 3D printers he has used. Dr. Scherer says this capability has led to effective word-of-mouth marketing because he is now able to accommodate patients with service that exceeds expectations: “I frequently have patients who break teeth right before a big trip or life event, and with 3D Systems’ NextDent printer I can now offer treatment in the same afternoon versus the temporary patches that are common practice using conventional techniques.”

Accurate & esthetic 3D printed outcomes minimize adjustments, maximize doctor time

According to Dr. Scherer, the accuracy of the 3D printer contributes to shorter delivery times and enhanced patient care as well. “The fact that the NextDent 5100 can produce models and dental prostheses in minutes instead of hours and achieve accuracy under 100 microns is a game changer for 3D printing in dentistry,” Dr. Scherer says, explaining that accuracy helps ensure he is delivering the highest quality care.

“3D printing has become so important to my clinical practice that I just can’t imagine going back.”

—Dr. Michael Scherer

With traditional molds and poured stone models, Dr. Scherer says fitting crowns, implants or bridges can take thirty minutes to an hour of adjusting to achieve the right fit. With 3D printing, fitting the same type of restoration takes significantly less time to adjust. “Doctor time on the computer is money well spent, because I find I am spending less time to fit prostheses due to the accuracy of the prints. Being able to shave off 20- to 50-percent of my clinical time more than pays for itself,” Dr. Scherer says.

The NextDent 5100 is powered by 3D Systems’ Figure 4 technology, with a non-contact membrane that delivers high quality, accurate outcomes on delicate parts. 3D printed support structures are also simple to add and fast to remove with 3D Sprint® software, reducing the post-processing time substantially and helping ensure undamaged parts. According to Dr. Scherer: “On another printer, just to remove the printing supports can take ten to fifteen minutes. On the NextDent 5100 it takes maybe 30 to 60 seconds. And that includes polishing!”

Improving the dental profession with digital dentures

In addition to his work at his practice, Dr. Scherer teaches courses on 3D printing and digital dentures that are open to other dentists, clinicians and laboratories interested in expanding their capabilities. He brings a patient from his practice and provides a step-by-step demonstration of his digital denture workflow. He is also active on social media with his group "FastTrack Dental CE", where he posts share-worthy experiences for discussion and learning. “The opportunity to interact with clinicians all over the world and share the vision of 3D printing in dentistry helps make the profession better and improve lives everywhere,” Dr. Scherer says. “3D printing has become so important to my clinical practice that I just can’t imagine going back.”

The accuracy of the NextDent 5100 makes fitting the prostheses 20- to 50-percent faster.