Details

Related

Consulting

※Product Overview※

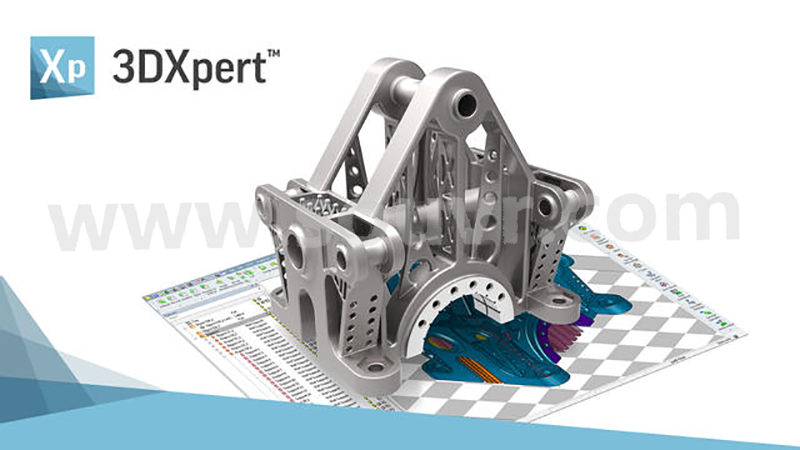

3DXpert

ALL-IN-ONE INTEGRATED SOFTWARE FOR ADDITIVE MANUFACTURING

Use an integrated solution to prepare, optimize and print, quality parts in record time

Overview

Minimize Your Lead Time to Quality Printed Parts

3DXpert is an all-in-one integrated software to prepare, optimize and manufacture 3D CAD models using additive manufacturing (AM). Supporting every step of the additive manufacturing workflow from design to post-processing, 3DXpert streamlines your process to quickly and efficiently transition from a 3D model to a successfully printed part.

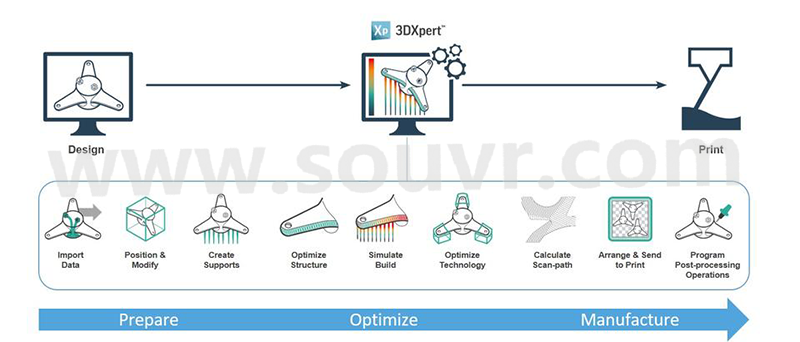

3DXpert Work Process - From Design to Manufacturing

With 3DXpert you no longer need to go back and forth between several different solutions to get the job done. Now you can use the same tool to: import part data; position the part; optimize the geometry and lattice creation; create optimal supports; simulate printing and post-processing to verify the final part will match design intent; set printing strategies; calculate the scan-path; arrange the build platform; send parts to print; and even program machining of the final product when necessary.

New 3DXpert Version 14 - Facilitate Metal Additive Production

• Support Multiple Print Heads - Increase Production Throughput while Maintaining Seamless Part Quality

• Facilitate Engineering Change Orders (ECO) - Quickly Respond to Changes

• Faster and Enhanced Simulation - Shorten Design to Manufacturing Lead-time

• Enhanced Orientation - Shorten Preparation Time with Better User Control

These are only some of the many new features and enhancements introduced by 3DXpert 14.

Why Choose 3DXpert

• The only true all-in-one integrated AM software

• The only history-based AM software

• The only AM software supporting hybrid modeling without conversion

• Unmatched speed to create, edit and view lattice structures

• Patent pending 3D zoning technology to define virtual volumes

• Unprecedented control over manufacturing process parameters

• Integrated build simulation minimizes build tryouts

Work With Any Geometry for Greater Agility, Quality and Speed

Seamlessly work with both B-rep (solid or surfaces) and mesh triangulation formats (e.g. STL). Save valuable time by eliminating the need to convert solid or surface data into mesh and improve data quality and integrity.

Facilitate Changes at Any Stage with History-based CAD Tools

Easily apply changes and edits to the model at any stage of the process, using history-based parametric CAD tools. Avoid losing the work you have done so far in case ECO (Engineering Change Order) is issued.

Shorten Print Time and Ensure Quality with Optimized Printing Strategies

Use the patent pending 3D Zoning to define virtual volumes without dividing the part to separate objects. Assign optimal print strategies to the different volumes taking into account design intent and part geometry and fuse them into a single scan-path.

Reduce Weight and Material Usage with Structure Optimization

Fast creation, editing and visual manipulation of lattice based structures (volume and surface texture). Lower part weight, material usage and printing time and enhance functional part properties while complying with the part mechanical specifications and maintaining its shape.

Minimize Tryouts with Build Simulation

Integrated build simulation in the design environment provides fault prediction for the entire manufacturing process, and allows corrections to be applied easily before sending parts to print. Minimizing the costly and time consuming number of tryouts ensures a repeatable and accurate manufacturing process with lower cost and time.

Enjoy the Ultimate Combination of Automation and Full User Control

Get an ideal mix of best practice templates along with unprecedented manual control to optimize the entire design and manufacturing process. Use pre-defined parameters specific to each printer, material, and print strategy or develop your own, controlling scan-path calculation methods and parameters.

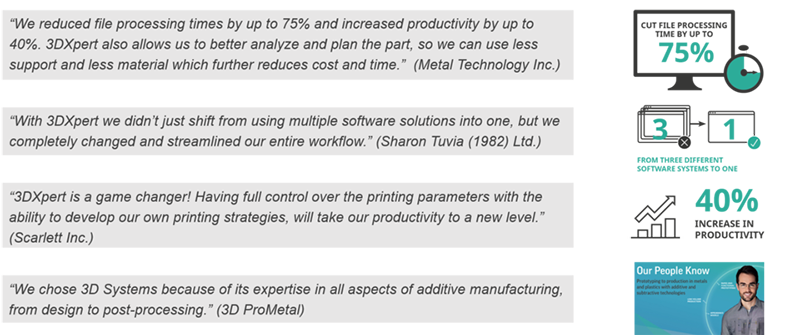

Customers Testimonials

Scarlett Inc.

“3DXpert is incredibly easy to use to set the conformal cooling channels. The advantages of 3DXpert to 3D metal printing and ultimately for a customer are faster turn around and more reliable results.”

Metal Technology Inc. (MTI)

Metal Technology Inc. (MTI) reduced print processing times as much as 75% and saw productivity gains of 40% using the unique capabilities of 3D Systems' ProX DMP Series printers and 3DXpert all-in-one metal additive manufacturing software.

3RD Dimension Industrial 3D Printing

"3DXpert is a great addition. It allows support generation, and provides real control of geometry including applying parameters to control print properties"

Features

Import Part

• Any CAD format - import data from all CAD formats, native read formats as well as virtually all mesh formats.

• Maintain CAD integrity - continue working with B-rep data (solids and surfaces) without downgrading to mesh, maintain data integrity including analytic geometry, part topology and color-coding.

• Analyze for printability - printability checks and automated healing of both STL and B-rep geometry.

Position & Modify

Orient and Position

• Real time analysis - receive immediate feedback on how part orientation impacts support areas, down-facing areas, approximated stress, print time and material consumption.

• Set orientation constraints - select faces or facets that should receive no supports or should not face downwards to ensure best surface quality.

• Automated best fit positioning - follow automated suggestions for part orientation that comply with predefined minimum criteria (e.g tray area usage, amount of supports, printing time, stress) or provide user-defined settings for each criterion priority.

• Visualize print environment - view build tray volume, gas flow and re-coater/roller directions.

Modify

• Parametric and history-based hybrid CAD toolset - use a rich set of parametric and history-based hybrid (b-rep and mesh) CAD tools as well as advanced direct modeling tools to improve part printability and prepare for post-processing operations (e.g., close holes and add material for machining).

• Facilitate ECO (Engineering Change Order) - automatically apply all design operations performed on a previous model version to an imported updated one, replacing time consuming manual operations with a fast, automated process.

• Shrinkage compensation - apply scaling to compensate for part shrinkage during the build process.

Optimize Structure

• Volumetric lattice and infill structures - hollow out parts while maintaining their shape and meeting their mechanical specifications.

• Surface texture - apply printable and conformal textures to achieve the required texture for each surface

• Lightning-fast optimization - groundbreaking volume representation technology (V-Rep) allows for extremely fast creation, editing, and visual manipulation of lattice structures, combined with history-based parametric features.

• Flexible automation - use a rich library of pre-defined lattice structures; design your own unit cell lattice structures and cell progression or import lattice structures designed in other systems.

• Lattice optimization - run an FEA stress analysis on lattice structure and surrounding, and optimize lattice elements based on that analysis to meet functional properties requirements while keeping weight, material usage and printing time to a minimum.

UPDATED

Design Supports

• Analyze supports requirements - automatically or manually identify regions requiring supports

• Easy creation - automatic supports setup based on best practice templates or your own templates

• Any type - select supports types from a rich library including wall, lattice, solid, cone, skirt and more.

• Full control - use a rich toolset to fragmentize, tilt, and offset supports to simplify their removal and minimize material requirements. Save your support structures as templates for future use.

Simulate Build

• End-to-end fault prediction - predict issues that might result in build failure or damage to the printer before sending the part to print. Verify proper part orientation and support design, and analyze the effects of taking the part off the build plate, removing supports, and applying heat treatment.

• Integrated within the design environment - easily apply corrections without going back-and-forth between multiple software solutions.

• Offload simulation - offload calculations to a separate computing platform and continue with your design work.

• Detect defects early on - receive layer-by-layer simulation results without waiting for the entire simulation process to complete.

• Compensated model - use a geometrical model that offsets the deviations created during printing, as a reference for adjustments to ensure the printed part matches the digital model.

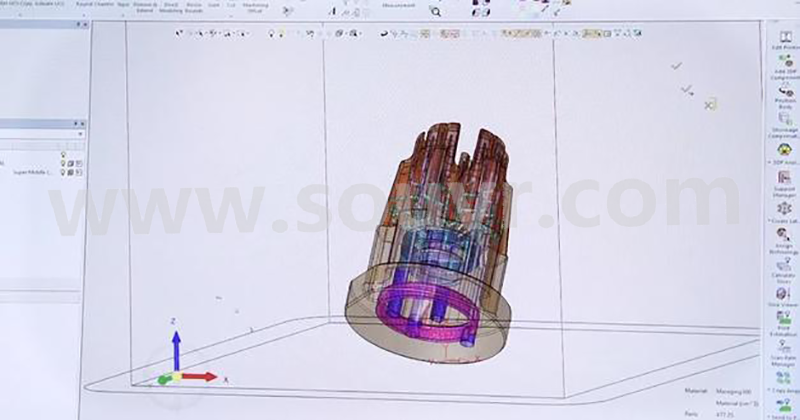

Optimize Printing Strategies

• Easily define areas - use the patent pending 3D Zoning to define virtual volumes using objects created by standard CAD operations, and assign specific print strategies to those volumes.

• Shorten printing time - automatically and manually assign optimal print strategies to relevant objects (e.g. supports, lattices, internal volumes, small features, high quality surface, circular area), matching required quality with printing speed and accuracy.

• Maintain part integrity - eliminate the need to divide the part into separate objects and use automated fusion of zones with different printing strategies to avoid weak spots and seam lines.

• Eliminate supports in hard to reach areas - set multi-exposure special printing strategies to ensure printing integrity without building supports.

Calculate Scan-Path

• Intelligent scan path calculation - combining control over print head (including auto balancing for 3D Systems DMP multi-laser printers) with zoning and part geometry to increase throughput while maintaining print quality.

• Shorten calculation time - Offload and distribute the calculation to additional computers. Quick and accurate preview of the actual scan path for selected slices prior to fully calculating the entire part.

• Ultimate flexibility - get the most out of your printer using pre-defined best practice parameters for each machine, material, and print strategy, or develop your own printing strategies with unprecedented control over scan path calculation methods and parameters.

• Validate the print process - navigate through the motions of the calculated scan path per each layer through the slice viewer.

Arrange Build Platform & Send to Print

• Arrange tray - automatically position and nest (2D and 3D) the parts on the build platform to best utilize the printing volume while eliminating collisions and interlocking, and create a united optimal scan-path for the entire build.

• Labeling - add labels to each of the parts placed on the tray or the tray itself to make them easily identifiable and combine their scan path with the build scan path.

• Verification - use a range of analysis tools to ensure all parts are ready for printing, view the combined scan path and estimations for print time, material consumption, and overall costs.

• Send to printer - send to printer as scan path information, generic CAD format (STEP, Parasolid, etc.), STL, 3MF or CLI slicing data

Program Post-Processing Operations

• Post-processing preparations - program machining and drilling tools to remove supports, machine high-quality surface areas, and drill, tap or ream holes.

• Shorten lead time - automatically receive printing preparation data as stock (including support geometry, support region contours, and machining offset objects), and apply smart machining templates to them.