HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin Asano Uses Geomagic 3D Scan Software to Drive In…

Asano Uses Geomagic 3D Scan Software to Drive In…

UCSF: Building for the human world

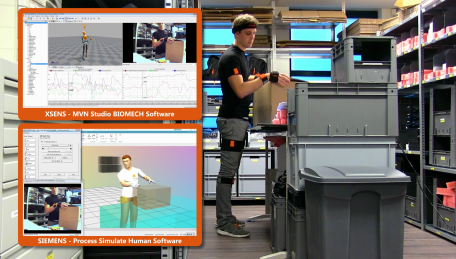

How Xsens’ inertial motion capture has revolutionized ergonomic design

For many, “ergonomics” is simply a byword for correct posture in an office chair and apt handling of a computer mouse. However, the school of thought surrounding ergonomics extends well outside the office environment.

Boiled down to its essence, ergonomics is about designing for the human experience of the world – something critical in all walks of life and in many different occupations. From lumberjacking to vehicle design, ergonomic thinking is vital in ensuring that people can perform tasks safely, with minimal injury and wear on musculature and joints. People might not feel the effects of ergonomic design instantly, but if it is lacking they will certainly feel it some years down the line.

There are many tools that enable improved ergonomics, but many emerging solutions are truly changing the game. Case in point: Xsens, which is opening new avenues of research and providing data that simply wasn’t accessible before.

Building for the human world

As an assistant professor in the Division of Occupational and Environmental Medicine at University of California, San Francisco, Dr. Carisa Harris-Adamson performs research that helps industries develop better ergonomic techniques that protect their workers.

Her department’s research includes pinpointing areas of biomechanical and cardiovascular strain in hotel room cleaners, for example, as well as how gastroenterologists are at risk for hand and elbow pain caused by intricate colonoscopy procedures. Her team is also researching how exoskeleton support systems can battle worker fatigue and increase productivity.

Although Dr. Harris-Adamson uses many tools in her research, it is starting to benefit in particular from Xsens motion capture technology: the very same technology used by over 600 universities and research centers worldwide.

Using Xsens MVN inertial mocap solutions, Dr. Harris-Adamson is capturing valuable readings with pinpoint data, which in turn is changing the way the world is designed around us.

Outside the volume

While optical motion capture solutions require an extensive studio setup and cameras to track markers on their subjects, Xsens presents a far nimbler offering. Xsens solutions are based on inertial technology, tracking kinematics data from detectors strapped to the performer’s body.

This means that researchers like Dr. Harris-Adamson can measure user experience of ergonomics design in normal, everyday work locations and routines, rather than having to create a simulation in the lab – which can ultimately skew results.

Furthermore, not only does this provide more accurate data, but it also saves time, money, and hassle overall.

“Xsens is such an easy system to use,” says Dr. Harris-Adamson. “We’ve been practicing with a colonoscopy study, and obviously having these physicians participate is not cheap – their time is expensive. Using Xsens technology, however, we get our research subjects in and out of the test in 10 minutes. It’s really quick and easy.”

Motion capture evolved

Traditionally, ergonomists used an electrogoniometer to measure body positions. This small device is placed over a joint during testing, but they’re cumbersome and temperamental, says Dr. Harris-Adamson, plus they derive less information overall.

Motion capture presents a much more robust research tool, but attempting to use optical solutions in the past have thrown up obstacles, as Dr. Harris-Adamson details:

“We once performed a hotel room cleaner study, where we had a professional actor and mocap volume set up in the laboratory to capture schematic data. That was a major pain, because every time the person went behind a bed, the markers couldn’t be seen by the camera. We wanted to look at the shoulder, for instance, but we couldn’t because we had so many problems with markers disappearing.”

Dr. Harris-Adamson’s department decided to find a motion capture system that could alleviate these issues. At first, they tried an alternative inertial technology based system to Xsens, but immediately ran into issues: “We experienced so much interference on the data – it was a total nightmare,” she remembers.

However, the team quickly switched over to Xsens and found a completely different experience at their fingertips – one that delivered accurate data, wherever, whenever.

The research team has also been impressed with how much capture data they can receive from a single session, compared to the limiting nature of electrogoniometers. For instance, while Dr. Harris-Adamson and crew might only require wrist and shoulder data, if they decide to also collect body measurements from the hip or knee, then the data is readily available without the hassle of setting up another test.

Changing the game

The University of California, San Francisco is using just one Xsens system for now, and students in the program can book it for their own research and experiments.

According to Dr. Harris-Adamson, students and industry visitors alike have been wowed by the Xsens technology, stating that the system “has that cool factor” that students and faculty alike have gravitated towards.

But ultimately, although the use of high-end technology in a research setting certainly makes tests that little more exciting, it’s the results that really matter. And there, Xsens excels: Xsens MVN technology makes it easier for Dr. Harris-Adamson’s team to take measurements in authentic work environments with minimal time, less discomfort, and less expense along the way. And, as the technology becomes more widespread, its benefits could help improve the way people work in all kinds of industries.

“Xsens has made biomechanics data collection fun – I used to hate it! I love the information, but it was just so painful to get it information out” says Dr. Harris-Adamson. “Xsens makes it a lot easier to collect what we need. What’s more, inertial measuring is definitely advancing our understanding of physical exposures in the workplace. And that’s very exciting.

“Xsens is changing the game,” she concludes. “Instead of mocking up a work scenario in the laboratory, we’re measuring information on actual workers while they’re doing their jobs. That is a huge thing in this industry – it could truly revolutionize the way we approach ergonomic design in future.”