HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin Asano Uses Geomagic 3D Scan Software to Drive In…

Asano Uses Geomagic 3D Scan Software to Drive In…

Altamira Cave: Digitizing History Using 3D Systems 3D Scanning Software

Artists and researchers reconstructed the Altamira Cave using 3D Systems 3D Scanning software by creating an exact and complete 3D virtual model of the cave.

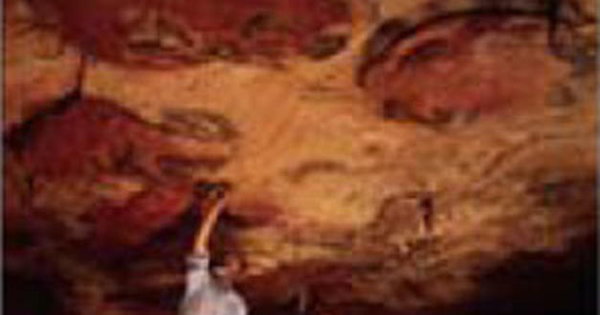

Replica of Altamira Cave

Altamira (Spanish for “high views”) is a cave in northern Spain famous for being the first cave in which prehistoric cave paintings were discovered. This discovery has forever changed the perception of prehistoric human beings as being artistically creative. Within the depths of Altamira, researchers found almost 200 paintings including 38 bison, 10 oxen, 26 horses, 1 mammoth and almost a hundred signs and symbols. The paintings were dated from the Paleolithic period, almost 15,000 years ago.

In 1978, it was decided that the preservation of these paintings were of the utmost importance. To avoid serious damage caused by the humidity and temperature changes caused by more than 177,000 visitors per year, closure of the cave to the public was deemed necessary. Through the years, pigment particles and even entire sections of the fragile paintings began falling from the roof. It was then decided that closure itself was not sufficient in preserving this site. A project to completely reconstruct the site was approved.

This enormous task was carried out by the Madrid company Tragacanto. A 3D scanner was used to scan every detail of the cave. With its unmatched flexibility, scanning speed, integrated LCD display and portability features, this made it the ideal high-tech scanning tool for the task.

Using the 3D scanner, over six million geometrical data points were acquired for the roof sections alone. After scanning for eight months and a surface area of 2600 square meters, the relief area of the so-called “kitchen” and “drawing-room” had already been recreated with a density of one point per every five millimeters.

Ancient drawings in the Altamira Cave

Based on the model generated through 3D Systems Geomagic Scanning software, and using CNC milling machinery, foam blocks were cut into different segments of the cave. After applying wax and silicon molds of the surface of the cave the final silicon wall sections were added.

The artists and researchers faced the daunting task to reconstruct the Altamira site used a similar technique that the original artists used. Here, mineral pigments diluted in water are being applied to the artificial limestone surface of the replica. This replica has the same absorbency as the original stone so that the wet pigment is naturally absorbed, just as in the original Altamira site. This was achieved by the use of ten tons of powdered limestone, which represented 80% of the total mass, the remaining 20% being synthetic binders. Also, a constant ambient temperature of 18 degrees Celsius was maintained, the same temperature as inside the original Altamira site.

This is an image of the Altamira replica “kitchen” under construction. This was the common living area of the Paleolithic people due to the ideal size, temperature, security measures and lighting conditions.

The Altamira replica found its home in a wing of a museum complex. It is estimated that half a million people will visit the museum every year. The incredible beauty of the cave’s paintings, which is still the finest discovery to date, is fully preserved in the reproduction. The Altamira reconstruction project has succeeded in earning the admiration from others researchers and museums in the world who are proposing a similar solution to preserve their cultural heritage. Without the latest digital input and output technologies this project would not have been possible.