HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin Asano Uses Geomagic 3D Scan Software to Drive In…

Asano Uses Geomagic 3D Scan Software to Drive In…

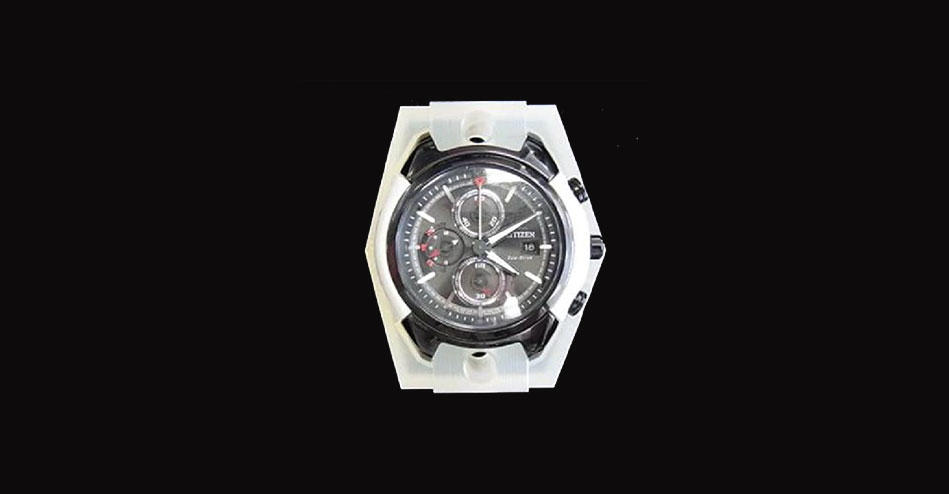

The ProJet MJP 3D Printer Saves Citizen Watch Time and Money

3D Systems’ ProJet® 3500 HD 3D Printer Saves Citizen Watch Time and Money

"With the high-precision 3D printed mock-ups of our wristwatch designs, we improved quality and saved three times the installation costs of our ProJet MJP within six months." -- Mr. Naito, Product Development, Citizen Watch

Citizen Watch introduced its first wristwatch in 1931. Since then, Citizen has grown into the global brand it is today, and earned a strong reputation through innovative products like the ‘Eco Drive’, which converts light into electrical energy, and radio-controlled clocks that use standard radio waves from an atomic clock to update to the correct time within 1 second every 100,000 years.

To maintain their confidential development strategy, Citizen relies on an in-house prototyping division. Before getting their 3D printer, Citizen used NC lathes in their machining center to create mock-ups of final watch designs and assembly jigs. Because this type of machining frequently adds costs and timeline delays, however, Citizen decided to explore their options in 3D printing to reduce the time and money their development center spent on prototypes.

Going from a designer’s sketch to a prototype involves repeated design reviews and adjustments, and machining a new prototype following each suggested change takes huge amounts of time and money. Since timeline restraints limited the number of verification models that could be made, Citizen could not explore all their ideas with machining. This limitation pushed the company to investigate 3D printing as a way to give its designers more time to thoroughly review designs during early stages so they could produce better final designs.

Of the ten 3D printers Citizen evaluated, 3D Systems’ ProJet MJP (MulitJet Printer) HD printer was the only one that satisfied all of their needs. The 3D printer produces durable, high-quality plastic parts using MultiJet Printing technology, and 3D Systems’ robust, UV-curable VisiJet® materials in an assortment of colors. With a net build volume of 11.75 x 7.3 x 8 inches, the printer provides a high speed print mode and delivers high definition prints with exceptional detail precision and surface quality.

Citizen ended up using its ProJet MJP for more than prototyping, however. “Since the VisiJet material can be dyed or painted, we can quickly and easily evaluate mock-ups that have the look of a finished product,” said Mr. Naito of Citizen’s Technical Development Division. “We saved three times the installation cost of our ProJet within six months, and it has helped us spot problems with physical models that we couldn’t see with CAD alone. We can now fine-tune and improve products before following through with the final mock-up, which has led to improved quality and valuable reductions in time and cost.”

Citizen is also using their MJP printer to magnify and print tiny structural parts at three times their actual size to examine their movement and invent new assembly jigs. Before getting its 3D printer, Citizen produced one variety of assembly jig. Since getting its ProJet, however, Citizen has created new jig candidates, enabling Citizen to make the best-suited shape for the required fit in the shortest amount of time. The MJP printer has transformed a 20- to 30-day process into overnight production and has been seamlessly incorporated into Citizen’s workflow as a powerful development tool.

“If nothing else, the ProJet MJP has an extraordinarily high level of precision, which is extremely important when piecing together small watch assemblies,” said Mr. Naito. “But the ProJet has other significant advantages as well. There is minimal distortion, warping, or variation in batches, and the surface quality is superb, with fine details and sharp edges. The material is of a higher quality, stronger and less brittle than competitors’ and has easy post-processing, with the ability to melt wax away. It’s also exceptionally easy to use. Even a beginner can master it in two to three days.”

Citizen’s 3D printer went into immediate operation and is now used by many of Citizen’s designers. It has made the company’s operations less confusing, and has inspired the watchmakers to continue looking for ways to use it beyond its research and development departments. “We want to move beyond traditional divisions and include departments that are directly involved with production and have pressing needs of their own,” Naito said.