HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin Asano Uses Geomagic 3D Scan Software to Drive In…

Asano Uses Geomagic 3D Scan Software to Drive In…

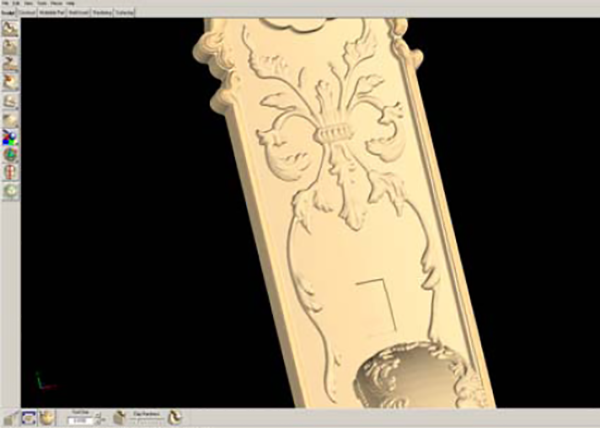

Geomagic Freeform Plus Transforms an Impossible Design Project Into Reality

Customer: Black & Decker – Hardware and Home Improvement and Baldwin Hardware Corporation, a division of Black & Decker

Black & Decker is a global marketer and manufacturer of quality products used in and around the home and for commercial applications. It is the world’s largest producer of power tools and accessories. Its household products business is the U.S. leader and the company is among global competitors in the small household appliance industry. In 2003, Black and Decker purchased Baldwin Hardware Corporation—a company committed to delivering innovative and exclusive products defined by “Timeless Craftsmanship®”.

The Goal

In an era where what is old is new, Black & Decker - HHI and Baldwin set out to create an exclusive line of door hardware that would evoke the artistic beauty and elegance epitomized in France during the 18th century. Their goal was to bring “old world craftsmanship”, including the imperfections inherent in the handcrafted design, into the modern machine-age of perfection, precision, and fast time-to-market. When they realized that it would be impossible to produce the products they envisioned using their traditional CAD tools alone, they turned to Geomagic Freeform Plus to help them bring the “Chateau” and “Craftsman” lines of Baldwin Archetypes to market.

The Challenge of Making a Design Reality

The project began with the collaboration between Jay Czerwinski, Manager of Industrial Design, his team, and the Marketing team. The Marketing team provided the over-arching design direction—the time and place of the 17th and 18th centuries in Europe resulting in styles of Rococo and King Louis XIVth-XVIth of France. Designers were asked to develop designs of door hardware that might have been created in that era had the technology of today been available. They were expressly asked not to design replicas, but rather to come up with new designs that evoked the essence of the past. The design team completed hundreds of 2D sketches, from which the Marketing team chose dozens of designs to use for their initial market research.

Working from the sketches, Black and Decker – HHI’s typical process at this point would have been to create simple NURBS models of the designs using Autodesk's Alias®, and then generate computer renderings with enough shading and lighting to be useful to the Marketing team to continue their market research to select less than a half dozen potential final designs.

When Jay saw the detailed, complex shapes of the leaves and vines in the designs that had been selected from the sketches; he realized that they could not make these models & computer renderings using their existing tools within a reasonable amount of time. The technical difficulties of using traditional CAD tools to model highly detailed, organic shapes with old world craftsmanship, combined with the need for flexibility to modify the designs to accommodate different internal locking mechanisms, threatened to bring the project to a standstill.

Geomagic Freeform Plus Delivers

To keep the project on track, Jay’s team used Photoshop® to paint flat-plan views instead of creating computer renderings. The Marketing team used these paintings to continue their market research while Jay talked with 3D Systems about how he could use Freeform to solve the challenges he was facing on the project.

Convinced that Geomagic Freeform Plus would enable them to quickly create complex, organic forms and sculptural details, and deliver the artistic look of “old world craftsmanship” they needed; and, that the 3D Systems team would support them as they integrated Freeform into their production workflows, Jay recommended it be added to their suite of tools.

Once the Marketing team had chosen the potential final product designs, the basic forms were modeled in Pro/ENGINEER and Alias. Then, designer Yos Singtoroj imported the CAD models into Freeform. Yos accelerated his initial modeling time by importing PhotoShop paintings into the software. He was then able to immediately flesh out the 3D model and add sculptural details using the carving and emboss tools. Using Freeform, Yos developed a unique, artistic style that enabled him to add a hand-crafted look to the designs—including imperfections that would show in the casting. Jay and Yos knew if these designs had been done using their traditional CAD tools, they would look too perfect, too straight and mechanical, too much of the machine age.

The final designs were then rendered in Freeform using the integrated mental ray® rendering engine. The Marketing team used the renderings for the final phase of their market research to select the 1 final design of the flagship product in the Chateau product line. Upon selection of the final design, Yos created the final model and handed it off to engineering for confirmation. Then Jay, Yos, and a team of designers began the task of designing the complete product line—60 additional products that matched the Chateau flagship product. Additionally, they have created custom pieces of hardware in the Chateau design for selected customers.

As they worked with the software, they also found the digitally modeled textures that can be created to be a significant time-saver and a boost to CAD productivity. For the Craftsman line of products, another of the Baldwin Archetypes designs, they needed a hammered metal texture that could be applied to the designs quickly and easily. They needed the texture to be consistent, but to still have the random variations found in “old world craftsmanship”. Using Freeform, Jason Veltz of the design team created a sheet of “hand-crafted”, hammered metal texture and used SensAble Technology’s surfacing tools in Freeform to export IGES files, which could be used by other CAD modelers using other software packages as needed.

The Results

“Freeform is a tool for the artist and for the corporate manufacturing world. This big mass production project— the development of the Chateau and Craftsman product lines—would have been impossible without Freeform,” said Jay Czerwinski, Manager, Industrial Design for Black & Decker – HHI. “Freeform has enabled us to respond quickly to our engineers’ requests to adjust our designs to meet varying hardware requirements. We’ve also been able to deliver unique, custom hardware solutions for our customers. And, perhaps most critical to us on this project, Freeform provided us with a way to convey the artisanship of the old world while having all the advantages of working digitally.”