Digital-based Robotic Inspection

Contact us:

TEL: +086-010-50951355 / FAX:+86-010-50951352

Email : cathy@souvr.com / Frank@souvr.com / Robin@souvr.com / sales@souvr.com

Details

Related

Consulting

※Product Overview※

Digital-based Robotic Inspection

Next generation robotic inspections.

Without programming.

More than a solution.

A "digital mockup based" revolution

The Digital-based Robotic Inspection software suite makes the most out of the industrial digital mockup, via direct connection to information systems, to allow next generation robotic inspections. Integrable into various robotic platforms and various sensors, it allows fully automated and highly robust robotic controls. All without programming or complex manipulations.

Fully automated robotic inspections

Trajectory planning

• Automatic choice of observation points according to the elements to be controlled

• Optimized simulation and planning of robot paths avoiding collisions

Analysis and arbitration

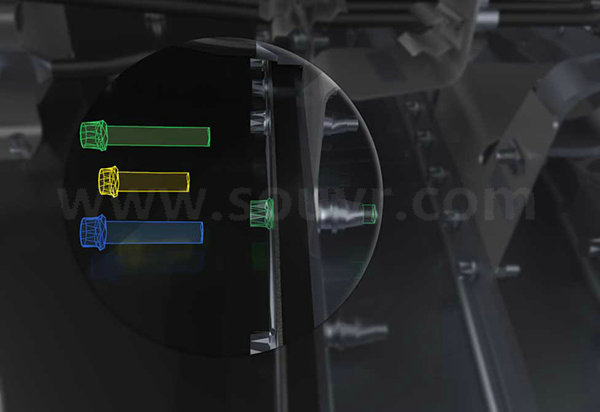

• Application of algorithmic operators based on the digital mockup using image (2D), digitization (3D) and CAD

• Application of control operators based on learning (reference images, machine learning, deep learning ...)

• Detection and characterization of nonconformities

Controlling and supervising

• Supervision of the progress of the control range

• Automatic control of the robot, of all elements of the cell (racks, sensors ...) and of capture phases

• Interaction with the supervision unit

Alerts and Reporting

• Issuing alerts for intervention and corrective action

• Generation of reports according to specific business rules

Always the best suited control

Leaning on a generic software suite integrating cutting-edge technologies, Digital-based Robotic Inspection adapts without specific development to various control sensors - 2D, 3D, multi-spectral, etc. - and various robots - cell, cobot, mobile, etc. It automatically detects a wide variety of defects using various methods.

Geometric controls

• Screw length

• Presence / absence of pieces

• Positioning of supports

• Interference

• Inversions

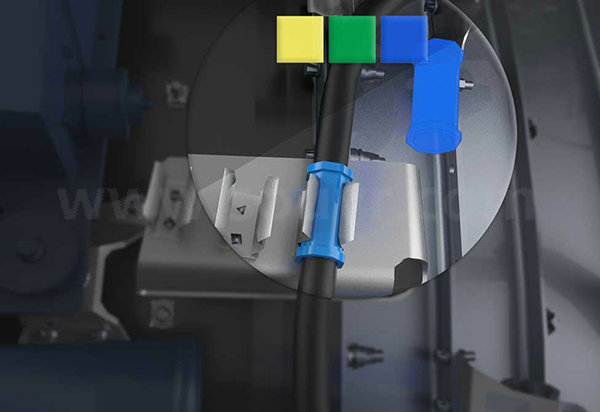

Colorimetric controls

• Object detection (e.g. flame)

• Presence / absence of objects (washers, plugs...)

• Marks

• Painting areas

Recognition - reading

• Texts (OCR)

• Serial numbers

• Nameplates

• Datamatrix

• Bar codes

• Symbols, marks

...

Comparative analysis

• Comparison by image recognition

• Learning based on reference data

• Machine learning

• Deep learning

• Image correlation

...

Optimized robot-human collaboration

Designed for effective operational complementarity, Digital-based Robotic Inspection optimizes robot-human collaboration in industrial contexts.

Communication during operations

Digital-based Robotic Inspection immediately detects any anomaly based on the digital mockup (or compared to a reference base if there is no CAD) and therefore issues an alert to the users concerned (operators, production managers, controllers) for intervention / corrective action.

Numerous advantages

Time saving

Time for the preparation, maintenance and evolution of the control ranges minimized

Agility

• Adaptability to different control cells

• Wide range of control features

• Evolves synchronously with the prodcut mockup

Reliability

• Robust controls

• Always updated ranges

• Immediate detection of anomalies

Efficiency

• Controllers focused on their expertise

• Analysis and arbitration facilitated

• Increased reactivity in case of anomaly

Traceability

Customizable control reports generated automatically

Cost saving

Low programming, maintenance and evolution costs