HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Altamira Cave: Digitizing History Using 3D Syste…

Altamira Cave: Digitizing History Using 3D Syste… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin

3D Scanning and Reverse Engineering with Geomagic Design X Helps NASCAR Cars Race to Victory

BMI helps NASCAR teams compete, fueled by 3D Laser Scanning and 3D Systems' Geomagic Design X

Cars scream around the track at speeds approaching 200 mph, yet a 500-mile NASCAR race can be decided by a few tenths of a second. To be a winner, NASCAR teams seek any advantage they can create. However, NASCAR has strict guidelines that specify nearly every aspect of the “stock” car. For BMI Corporation, experts in computational fluid dynamics (CFD) analysis, designing the most aerodynamic cars that conform to NASCAR’s restrictions means using leading edge technology. A crucial part of their technology arsenal is Geomagic Design X.

BMI co-founder, Michael Henderson, provides the expertise behind their aerodynamic advantage. Henderson spent 32 years with Boeing, mostly as head of research, and led the company’s early work with CFD. For Henderson, who is also involved in the development of a supersonic business jet, there is little difference between aircraft and racecars in terms of aerodynamics. While racecars are far from supersonic, Henderson believes that aerodynamic excellence will break a few barriers.

“CFD is a critical tool for refinement of cars racing in a NASCAR series. It helps us to visualize the changes that will translate to more speed. Other teams rely on wind tunnels, but the results are inaccurate. Interaction with the floor, walls and ceiling can throw measurements off by 20 percent,” Henderson said. Some teams are adopting in-house CFD, however, according to Henderson, “Our edge is the expertise in performing CFD simulations and interpreting the results.” Expanding this expertise, Henderson’s latest hire was John Anastos, an aerospace engineer with a background in CFD. Anastos supports BMI through its sister company, Advanced Vehicle Research (www.avrsc.com) based in Greenville, SC. AVR performs aerodynamic analysis for NASCAR teams, as well as IRL, Formula 1 and Champ teams.

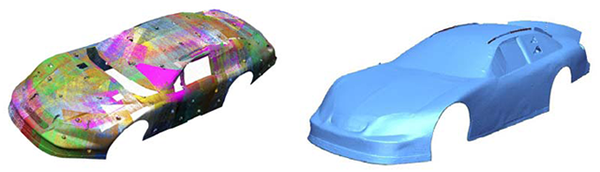

At AVR, Anastos’ technology includes Geomagic Design X, a Konica Minolta laser scanner and two sophisticated CFD software programs that Henderson used at Boeing. The laser scanner produces point clouds that define the entire car, including the undercarriage, and the software from 3D Systems processes the point clouds to produce surface data that fuels the CFD programs. Anastos said, “The 3D scanning process is essential because each car is unique; they are basically handmade.” He also noted that scanning the undercarriage is critical in the analysis because this is where downforce is created. “We tune the car’s design to accelerate airflow along the undercarriage. It acts like a plane’s wing, only in reverse,” he said.

According to Anastos, AVR looks for minor adjustments, some almost undetectable, that yield an increase in available horsepower. He said, “With NASCAR’s stringent rules, cars are closely matched, so these small changes can be the difference between winning and losing.” NASCAR’s templates give teams only 0.070 to 0.50 inch design latitude. He continued, “On a track like Atlanta Motor Speedway, a five percent decrease in drag is the equivalent of a 25 horsepower (hp) gain, which gives an increase in lap speed of 0.5 mph. On the same track, a 0.1 increase in downforce coefficient gives an increase in lap speed of 1.8 mph. It would take a 70 hp gain to get the same results.”

“Without a smooth, precise 3D definition of the car, our CFD results would not be accurate enough to detect these fine adjustments,” said Anastos. To capture every detail of the car, AVR will do 150 laser scans, which takes eight to 10 hours. In that time, the laser scanner will collect nearly 20 million points for a typical car. Once scanning is complete, Anastos brings the point clouds into Design X where he filters the data to remove noise, artifacts and redundant points. This reduces the point clouds to five million data points.

Anastos uses Design X to align the individual scans to one another and merge them into one data set. “As I am merging, I use the software’s Accuracy Analyzer to check that the overall dimensions accurately reflect the car,” said Anastos. He then deletes markers, fills gaps in the point cloud and massages the 3D data. “During this step, I really enjoy the automated processes that 3D Systems offers. For example, the one-button healing function, which checks and repairs defects in the scan data, is huge. It saves me so much time; I don’t know what I would do without it,” he said. Anastos notes that Design X is very comprehensive yet simple to learn. “With a background in CAD, Design X is rather intuitive. I found it very easy to learn, and the software does everything I need it to do,” he said.

Anastos builds the CFD-ready model with Design X’s NURBS surfacing tools. Since this CAD data is parametric, he can easily edit the model at any point in the process. When surfacing is completed, he imports the model into the CFD program.

AVR starts with an analysis of the car’s shell using CFD to seek the small changes that yield performance gains. They then begin adding parts, such as tires, spoiler and undercarriage, and repeat the analysis with each addition. “We do the build up so that we can see the incremental changes and the cumulative effects of each part of the car,” commented Anastos. Once AVR achieves optimal drag and downforce, the car goes to the test track or wind tunnel to confirm the analysis. “Others start with the wind tunnel. We turn the process upside down,” Anastos said.

With the introduction of the Car of Tomorrow (COT), which NASCAR designed to make racing safer, more competitive and cheaper for the race teams, AVR’s challenges increase. NASCAR’s changes make the cars less aerodynamic, and templates are more stringent. Anastos said, “For the Car of Tomorrow, we will be playing with flow on the undercarriage. This is where the race will be won.”

Whether it is the current templates or those of the COT, AVR is using 3D scanning and CFD to let NASCAR race cars fly like the wind.