HOT

Metal Technology (MTI) forges new path with meta…

Metal Technology (MTI) forges new path with meta… Reaching the Outer Limits with GibbsCAM and the …

Reaching the Outer Limits with GibbsCAM and the … Planetary Resources Uses 3D Printed Casting Patt…

Planetary Resources Uses 3D Printed Casting Patt… Rapid Part Replacement Ready for Take Off?

Rapid Part Replacement Ready for Take Off? Bushnell Verifies High Detail Optics Designs wit…

Bushnell Verifies High Detail Optics Designs wit… Birdstone Delivers Schweppes Redesign with 3D Sy…

Birdstone Delivers Schweppes Redesign with 3D Sy… 3D ProMetal Optimizes Next-Gen Medical Component…

3D ProMetal Optimizes Next-Gen Medical Component…

3D ProMetal Optimizes Next-Gen Medical Components with 3DXpert AM Software

3D ProMetal specializes in manufacturing surgical devices and components used in medical implant production. Co-founders Boaz Harari and Uri Shasha have more than 20 years of experience designing and manufacturing medical components using conventional manufacturing methods.

Recognizing the limitations of conventional manufacturing and the new opportunities offered through Additive Manufacturing (AM), 3D ProMetal established a 3D printing service bureau to specialize in medical components that benefit from being produced additively.

Advancing Medical Device Manufacturing with Metal 3D Printing

3D ProMetal’s use of additive manufacturing focuses on cases where the technology delivers the greatest advantages.

According to Harari, customers come to 3D ProMetal for two key reasons: “First, our lead time for prototypes is days instead of weeks. More importantly, they come to us for complex geometries that either cannot be manufactured at all using traditional methods, or where 3D printing is more cost-effective.”

In some cases, the design of these complex structures consolidates multiple parts, saving assembly work and extending part durability. In other cases, more complex designs enable enhanced functional properties.

3D ProMetal selected its metal printing solution after a thorough benchmark of the leading 3D printer vendors. “We chose 3D Systems because of its expertise in all aspects of additive manufacturing, from design to post-processing,” says Shasha. Specifically, 3D ProMetal was impressed by the quality offered by the ProX® DMP 200 printer for its small size parts.

The material it selected to use is 3D Systems’ LaserForm® 316L – a highly corrosion-resistant stainless steel that can withstand frequent sterilization. “We are able to push the printer beyond what we expected – we can print taps as small as M1.6 with excellent quality, and thin stainless-steel parts with walls as thin as 0.3 mm,” adds Shasha.

Beyond the Printer: Preparing and Optimizing for AM

It takes more than a good 3D printer and suitable material to get successful metal prints.

3D ProMetal uses 3DXpert™, the all-in-one integrated AM software by 3D Systems, to prepare and optimize the 3D CAD models for printing. A typical workflow includes the following steps:

Importing the 3D CAD model – 3DXpert is unique in its ability to work with B-rep (solid and surfaces rather than mesh geometry), ensuring data integrity and accurate geometry. “We ask our customers to get B-rep files (original CAD documents like SOLIDWORKS documents, or STEP and IGES files) as it is much easier to define areas compared to working with mesh-based models,” says Shasha.

Positioning the part on the build tray – 3D ProMetal takes advantage of 3DXpert’s automated analysis and positioning tools to set the right orientation of the part on the build tray. “We know which areas must have high quality and therefore cannot face downwards or have any supports on them, and we use automated positioning analysis to orient the parts accordingly,” explains machine operator Yaki Nissim.

Modifying the part - 3DXpert allows 3D ProMetal to use a hybrid (B-rep and mesh) CAD toolset to optimize designs for 3D printing and prepare them for manufacturing while meeting the required specifications (e.g., removing internal features that require supports or changing the angle so supports are not required).

Setting supports – 3D ProMetal uses 3DXpert’s automated tools as well as manual controls to set adequate supports and eliminate deformation while maintaining surface quality.

Slicing the file, arranging the build plate, and sending the job to print – To maximize printer utilization, 3D ProMetal relies on 3DXpert’s automated tray arrangement to place as many parts (either identical or different) as possible on the build plate.

According to 3D ProMetal’s executives, 3DXpert is instrumental to the company’s success in multiple ways. Not only does the software help the company deliver the highest quality parts with the shortest possible lead times, it also ensures that customers get accurate time and cost estimates by using 3DXpert’s print estimation tool to assess time and material for all quotes. “We have fine-tuned the tool to the point where we now have print estimation accurate to the minute,” says Shasha. “This ensures that our quotes are competitive while protecting our profit margins.”

A Typical Use Case Where Additive Adds Value

Self-expanding stents are used in transcatheter aortic valve implantation (TAVI) procedures. These stents are usually made of Nitinol, a nickel and titanium alloy, taking advantage of the material’s unique super-elasticity and shape memory properties. Super-elasticity is the ability to accommodate large recoverable strains within a given temperature range. Shape memory is the ability to deform at a given temperature and recover to the original shape when heated above the transformation temperature. These properties enable the stent to be loaded into a tube-shaped delivery system and then expand to its functional shape upon deployment in the body.

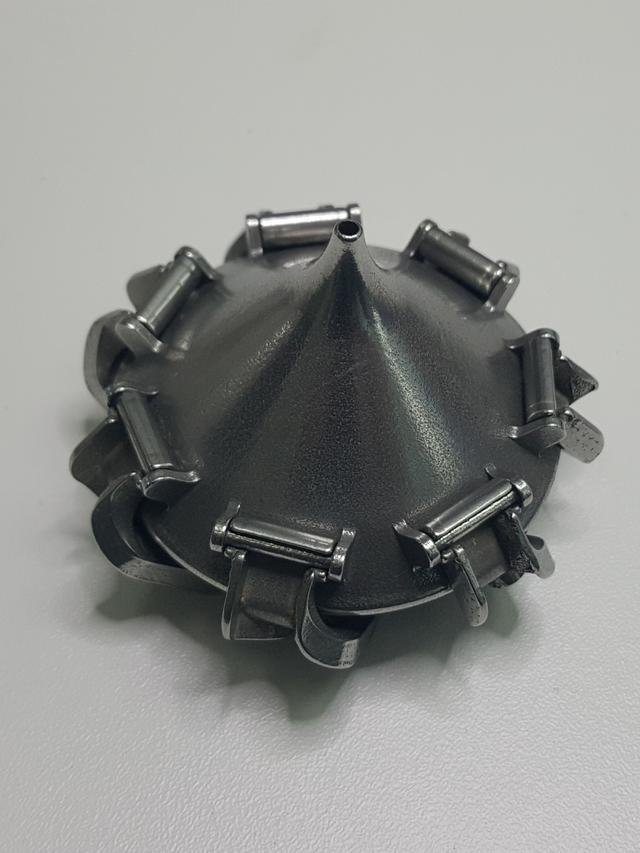

To shape Nitinol to the desired structure, a specially designed mandrel element is used, which is where 3D printing comes into play. The mandrel is made of multiple parts with a complex geometry that is very difficult to manufacture using conventional techniques. In addition, since the mandrel is used when the Nitinol is heated, it must have a perfectly uniform convection. To achieve that, the walls have to be extremely thin – which combined with the complex geometry, makes manufacturing with conventional techniques very challenging.

Using 3D Systems’ ProX DMP 200 printer and 3DXpert software, 3D ProMetal is able to manufacture highly complex stainless steel mandrels with surface thicknesses of only 0.4 mm. Moreover, they are able to print the screw taps instead of welding nuts onto the mandrels, which eliminates the need for additional assembly work.

A Growing Market Going Forward

3D ProMetal’s founders see a great opportunity for additive manufacturing to become a catalyst in reshaping how medical devices are made in the future.

“Product designers benefit from using design software that makes them aware of the implications of their decisions on print quality and cost – things such as part orientation, positioning, and supports,” say Harari and Shasha. “We can produce higher quality parts and get things done more efficiently than ever before thanks to integrating additive manufacturing, and the benefits will only continue to grow as more customers understand how to take better advantage of everything AM can offer.”

Get in touch for more information about how 3D Systems’ solutions could optimize your application or business.