HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin Asano Uses Geomagic 3D Scan Software to Drive In…

Asano Uses Geomagic 3D Scan Software to Drive In…

GibbsCAM Helps Customer Meet High Risk Deadline For SpaceX

Arizona Shop Meets High-Risk Deadline for Launch of Secret U.S. Government Payload

Employees at Sonic Aerospace in Chandler, Arizona credit GibbsCAM software as one of the main reasons they consistently deliver parts on time to their customers -- first-tier suppliers to major aircraft and rocket companies.

Faster. Cheaper. Better. Meeting one or more of these demands can provide long-term success for a supplier in any industry. If a shop can help its customers achieve all three before the first part is made, it can also become a valuable partner, gaining the loyalty and repeated business that keeps it busy through the worst of times.

Providing engineering services, to make parts faster, cheaper and better, before machining a production part, is a common practice of Sonic Aerospace, with 15 employees working in its 10,000 ft² facility in Chandler, AZ. Many of its customers are first-tier suppliers to the major aircraft and rocket companies, including NASA, Boeing, Honeywell, Sikorsky, SpaceX, and the United Launch Alliance.

When Mark Willmering opened Sonic, in 1989, the shop made parts with manual machines. In 1993, when he acquired his first CNC machine, he researched CAM software, and quickly settled on GibbsCAM, because he found it to be the best available on a PC, the easiest to use, and the most supported in the area. Since then, his shop has continued to rely on GibbsCAM to program all machining-center work, adding the 4-axis modules along the way.

Although engineering accounts for no more than 20 percent of Sonic's business, it is a key differentiator. Willmering gives great credit to his engineering manager and CNC programmer, Tarry Latham, for the engineering the shop provides, because Latham knows the entire manufacturing process and the shop's capabilities.

Latham began with manual machines in the early 1970s, moved through punched-tape NC, then to CNC, using various CAD/CAM systems from mainframes to PCs. After moving to Arizona in 1979, he has worked on nothing but aerospace. His introduction to GibbsCAM came when he began working for Sonic in 2001.

When not doing engineering, purchasing materials, or determining machining strategies, he is programming the shop's four 4-axis CNC machining centers with GibbsCAM, which he likes for its flexibility and for the efficiency from ease and speed of use. He also appreciates its consistency, something lacking in other CAD/CAM systems he has used. "GibbsCAM doesn't change icons or move functions around when they add capabilities, so you don't lose productivity with new releases, and you don't have to go for retraining," he explains.

The flexibility he likes is there, in part, because the software does not force the user to do things in a specific order or method. There are various ways to approach a part, to define tools, to select a model or surfaces for machining, and choose any of multiple machining styles. For a simpler time-saving example, GibbsCAM lets the user store tools, machining styles, or processes under any name for later use. However, when Latham works with family-of-parts, he retrieves a completed project, saves it under a new name, and loads the new model, saving the same time his own way.

He says the typical job is 6 to 8 pieces, and fairly complex, if not in geometry, certainly in the motion and rotations required to machine all the features, and he estimates that 80 percent of the work is 3-axis and 20 percent 4-axis. Many parts are first turned and bored on Okuma CNC lathes, which are programmed at their controls with Okuma's software. When jobs are too complex, the machinists go to Latham for GibbsCAM programming.

Although Sonic machines many castings, Willmering is beginning to see a migration toward machining from billet because casting is becoming more expensive. Customers say a years-long consolidation in the industry has created a casting monopoly that leaves customers little choice in price and delivery. The higher price and long lead times of casting make machining from billet much more appealing for short-run jobs, because machining time can be a small fraction of the casting-plus-machining lead time.

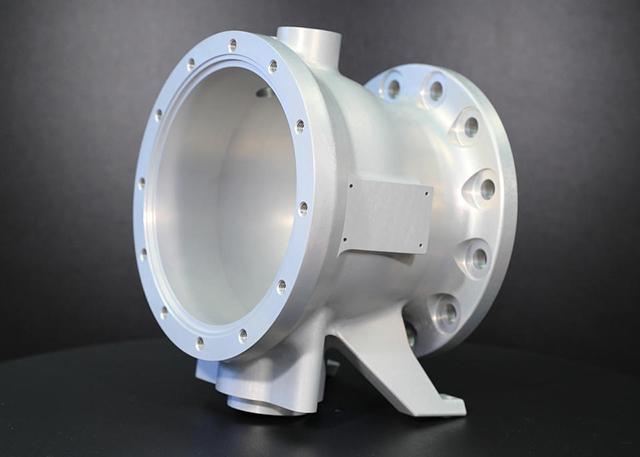

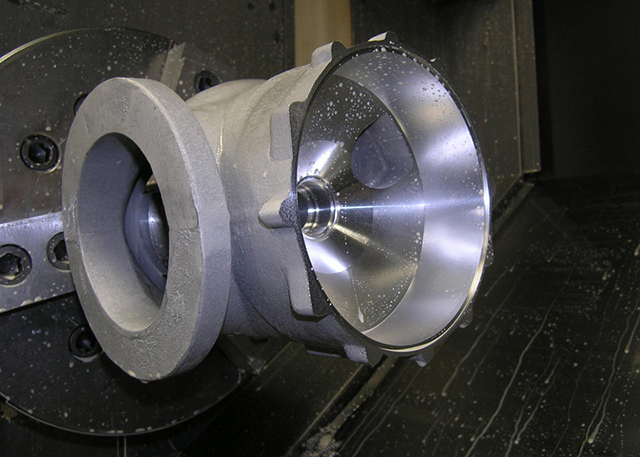

Sonic likes to demonstrate its direct-from-billet capabilities with a "4-inch fill and drain valve body," the smallest of a family they make in four sizes for the Delta rocket. The part incorporates a spherical "ball valve" and smaller parts that Sonic manufactures. When it was a new design, Latham worked with customer engineers to reduce processing and cost, going through a few iterations to arrive at a part that became a regular, small-batch order for the shop.

The part geometry highlights many of Sonic's machining capabilities, some turning, some of Latham's tricks to machine what appears impossible, and a lot of GibbsCAM functionality. After initial boring on a lathe, the part is fixtured on a mill's rotary table, where standing bosses, two "legs" at irregular angles, mounting flanges on both ends, and multiple drilled and tapped holes are machined with 30 to 40 tools. Most surprising is that the part was fixtured just once, and everything was machined on the rotary table, enabled by 12 to 18 rotations.

Aside from the fast and easy way to define coordinate systems for rotary functions, Latham says the GibbsCAM feature he uses most for billet machining is Surface Flow Cutting because, he says, "In addition to machining the surface right off the model, it allows extrapolating a sheet of surfaces, from a few to a few hundred, to machine as a single surface. It is really efficient, allowing very high feeds and speeds with large step-overs for roughing, and a good surface with a final .010" to .015" step-over. I've used it for years and years."

Perhaps the most valuable single feature is OpSim, the GibbsCAM toolpath simulation utility, which allows rendering individual tool operations, groups of operations, an entire program, or between selected start and stop points. For easier diagnostics, it allows using a different color for each tool or operation. Additionally, it has the Compare option within Analyze Cut Part, which displays in red any gouging or overcutting into the part model or stock body. "I use it for every job," says Latham. "It's a must."

Meeting the Deadline

Willmering is highly pleased with Latham's engineering, GibbsCAM programming, and CNC machining, whether making prototypes from billet or machining castings. To demonstrate his confidence in this combination, he cites a high-risk rush job done late last year.

A SpaceX supplier needed to have castings for six oxidizer valve housings machined and delivered within two and a half weeks, so it could meet delivery of the assemblies in time for SpaceX to complete the Falcon 9 rocket to launch a secret U.S. Government payload into orbit at a specified date. The customer had only six good castings and a set-up piece. The best lead time available for new castings was 22 weeks. None of the six castings could be damaged. They were now mission-critical parts. Without all six delivered on time, Sonic's customer would pay a hefty penalty fee, and the government mission would be delayed or scrapped.

Sonic customers nearly always provide only a print with castings, never the CAD model, so a significant amount of time would be required for programming. However, as Tarry Latham explains, "What I like most about GibbsCAM is that you can do a lot of things almost in the blink of an eye."

Willmering recruited all his engineering, turning, milling, deburring and inspection people to work on the project, and for his customer, the anodizers dispensed with lead time and anodized the parts in a day. "Because we have GibbsCAM, we were able to program the parts quickly and start machining them flawlessly," he says, "but it took our whole team to deliver on time. We must have saved our customer a huge amount of money, because the program manager made the effort to write and thank us, specifically, for that one job."

See the story as published in Modern Application News.