HOT

Production-Quality Lenses Directly from SLA 3D P…

Production-Quality Lenses Directly from SLA 3D P… Forging Ahead with Solar Energy and GibbsCAM CNC…

Forging Ahead with Solar Energy and GibbsCAM CNC… GibbsCAM Software Helps Race-Team Mechanics Beco…

GibbsCAM Software Helps Race-Team Mechanics Beco… Metro Aerospace Introduces 3D Printed Part for F…

Metro Aerospace Introduces 3D Printed Part for F… GibbsCAM Enables Rover Exploration Vehicle Parts…

GibbsCAM Enables Rover Exploration Vehicle Parts… Designing a Custom Boot for an Injured Penguin

Designing a Custom Boot for an Injured Penguin Asano Uses Geomagic 3D Scan Software to Drive In…

Asano Uses Geomagic 3D Scan Software to Drive In…

The Outside Speeds Product Design with High Quality 3D Models

The Outside merges creative design and cutting edge CAD technology to make products better, faster and cheaper for clients that include Mattel, Rubbermaid, Kodak, Fisher-Price, and Marvel.

Kyle Houchens, owner and founder of The Outside, purchased Geomagic Sculpt (previously Geomagic ClayTools) so he could efficiently add texture to models. Many of his clients have in-house rapid prototyping systems and use his models for focus groups, functional testing, and in some cases catalog photography. What started with a simple need to add texture to a drill grip turned into a revolutionary development system that has cut countless time and money out of his client’s development cycles.

With one job Kyle paid for the price of Sculpt. His client was blown away. They were able to pull the fully textured part out of the stereolithography printer vat, sand it lightly, paint it and get feedback from a consumer focus group that proved the design was going to be successful.

Dramatic Improvement in Speed and Quality of Models

“Sculpt has dramatically sped up my workflow, improved model quality and detail, and since in my business time is money, significantly boosted my bottom line,” says Kyle. “For me, Geomagic Sculpt has revolutionized the way I work, and has given me a significant competitive advantage.”

Kyle’s work with Sculpt has evolved into a hybrid workflow utilizing Sculpt and Rhino™ to complete models faster and better than ever before. Following are examples of how Kyle used the software to solve specific design problems allowing him to get the job done faster, better, and cheaper.

Blade

VR

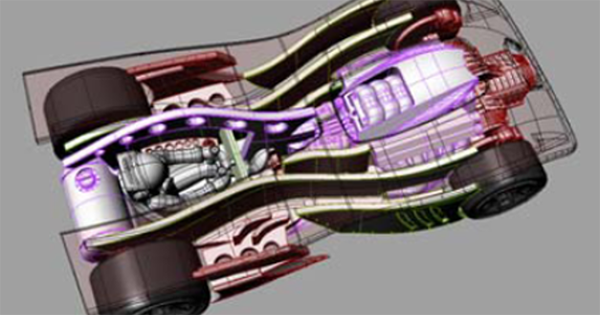

“In this case, the rear end of the vehicle had a complicated transition that was proving troublesome. Instead of spending the time to work through this in a NURBS environment, I got it close in Rhino, moved into Sculpt and “sanded out” the visible seam. The result was a perfect transition in an important highlight area, in minutes, not hours.”

Nerve Hammer and Preying Menace

"These models show Sculpt (models are shown right below) used for its simplest time savings. I was able to rough out the models in Rhino (no trims, blends or transition surfaces), get client approval, and then add all fillets, transition surfaces, cut lines and textures. The files were then exported as fully textured STL files and sent to the client for SLA output. The average time for these models was 15- 20 hours," says Kyle.